A researcher team which includes experts from Singapore-MIT Alliance for Research and Technology (SMART), MIT's research enterprise in Singapore and National University of Singapore (NUS) have developed a new technology that is capable of accelerating the genetic engineering of microbes, which can be used to manufacture chemicals meant for urban farming.

This new revolutionary technology will result in a faster, cheaper, more accurate and near-scarless plasmid construction, by using standard and reusable parts, that is compatible with most popular DNA assembly methods.

This research paper titled, "A standard for near-scarless plasmid construction using reusable DNA parts," will be published this month in the journal, Nature Communications.

It should be mentioned that this project is a part of the SMART Interdisciplinary Research Group (IRG) – Disruptive & Sustainable Technologies for Agricultural Precision (DiSTAP).

The IRG develops new technologies to enable Singapore to improve its agriculture yield to reduce external dependencies, as the Republic is dependent on imported food and product.

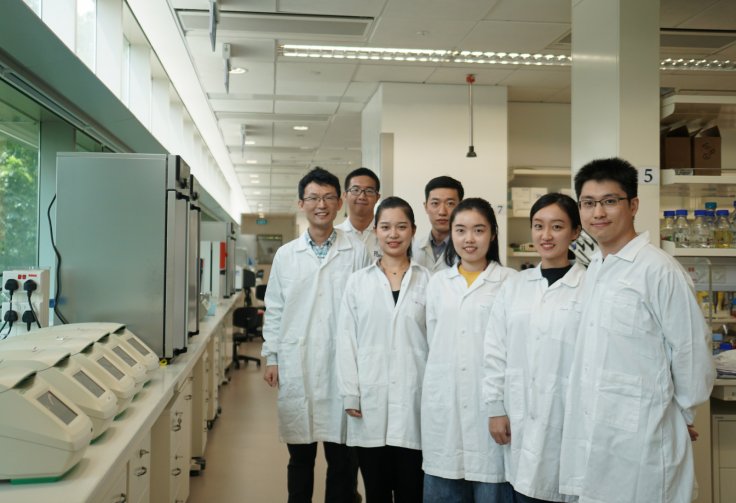

Kang Zhou, a DiSTAP Principal Investigator who is also an assistant professor at the NUS Department of Chemical and Biomolecular Engineering (ChBE) and Xiaoqiang Ma, a postdoctoral associate at SMART, led the development of the technology while working on the options to support their colleagues who were working on enhancing vegetable yield in the country's urban farms.

The team was also exploring ways on microbial fermentation which create fertilizers, nutrients and non-synthetic pesticides for urban farms, in the form of small molecules. Ma said that their objective was to create a technology that can engineer microbes faster and at a lower cost.

"Current technology is expensive and time-consuming. Researchers have to order customised materials from suppliers which takes a while to arrive. They also often use only 1% of the material, leading to wastage. As each material is customised, researchers have to re-order each time, which further delays and add costs to the production," Ma added.

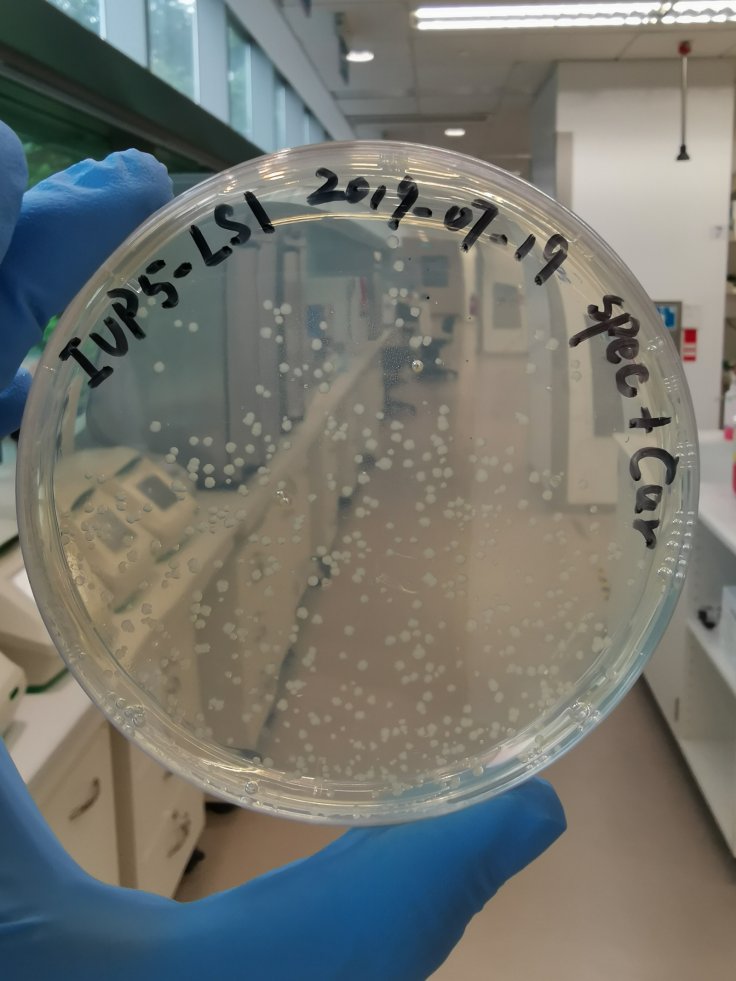

The new Guanine/Thymine (GT) DNA assembly technology can significantly change things by enabling genetic engineers to reuse genetic materials. It provides a simple method to define the biological parts as standard DNA parts.

Previous attempts at creating standardised materials had an accuracy of up to 50 percent but the GT technology is able to reach an accuracy of close to 90 percent.

As a near-scarless plasmid construction, the technology is substantially faster, being able to stitch up to seven parts to a DNA as opposed to only 2two parts for other methods of similar accuracy.

"Being able to provide an accuracy of close to 90% for genetic materials while connecting up to 7 parts to a DNA is a game-changer in the creation of genetic materials by using standard parts," said Zhou.

Zhou and the team believe that a huge cost and time savings will enable the development of new fermentation processes "that can manufacture green chemicals to make urban farming in Singapore more efficient and safer. This technology is also applicable to all genetic engineering fields outside of agriculture, and we are actively looking at ways we can deploy it for easy access."

In terms of commercialisation of plans, the researchers are also planning to set up an e-commerce platform which can quickly create and distribute these genetic materials to researchers around the world. It will be the first such platform for reusable genetic engineering materials in the world.