Would you like to dabble with a leaf that produces syngas? Right now this gas is a product of fossil fuels. However, if you want to up your carbon footprint, you can use an 'artificial leaf' that leverages just sunlight, carbon dioxide and water to make syngas. Eventually, it can even be the power centre to create a liquid fuel that works as a petrol alternative.

Scientists at the University of Cambridge showed that this can be done. The artificial leaf can work efficiently on clear as well as overcast days, while unlike the present industrial procedures to produce syngas, it does not emit carbon dioxide into the atmosphere.

Syngas is used to manufacture a wide range of commodities, such as fuels, pharmaceuticals, plastics and fertilisers. The results were reported in the journal Nature Materials.

"You may not have heard of syngas itself but every day, you consume products that were created using it. Being able to produce it sustainably would be a critical step in closing the global carbon cycle and establishing a sustainable chemical and fuel industry," said senior author Professor Erwin Reisner from Cambridge's Department of Chemistry, who has been working on the goal for the past seven years.

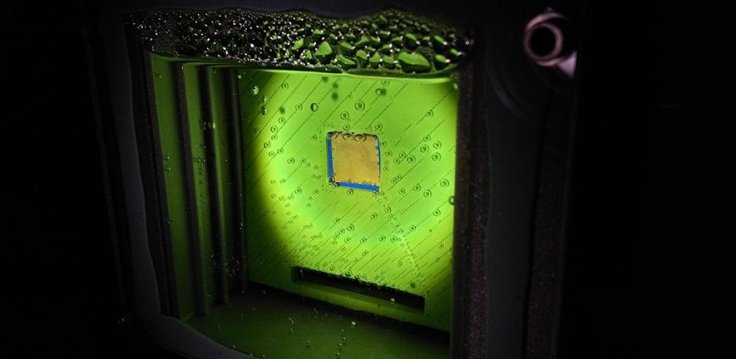

The team used a device that is actually inspired by photosynthesis, a natural process that is leveraged by plants to harvest energy from sunlight and carbon dioxide to produce food. A couple of light absorbers, just like the plant molecules that harvest sunlight are blended with a catalyst that has been made from cobalt, an element that is abundantly prevalent.

If the device is submerged in water, there is one light absorber that leverages the catalyst and produces oxygen. Another one undertakes the chemical reaction to bring down carbon dioxide and water and instead turns it into carbon monoxide and hydrogen. This is the process that leads to forming syngas. The light absorbers were found to be functional even when the levels of sunlight were dim under rainy or overcast skies

"This means you are not limited to using this technology just in warm countries, or only operating the process during the summer months," said PhD student Virgil Andrei, first author of the paper. "You could use it from dawn until dusk, anywhere in the world."

The research was carried out in the Christian Doppler Laboratory for Sustainable SynGas Chemistry in the University's Department of Chemistry. It was co-funded by the Austrian government and the Austrian petrochemical company OMV, which is searching for techniques to improve the sustainability of its business.

It is due to the blend of materials and catalysts that the Cambridge researchers were able to sustain syngas production. The scientists have used syngas as a building block in the manufacture of liquid fuels. "What we'd like to do next, instead of first making syngas and then converting it into liquid fuel, is to make the liquid fuel in one step from carbon dioxide and water," said Reisner, a Fellow of St John's College too.