Nanyang Technological University (NTU), the infrastructure specialist JTC and consultancy company Prostruct Consulting Pte Ltd joined hands to developed a ready-to-stick wrap to protect concrete pillars and help the construction industry.

The newly developed technology can be used to rehabilitate ageing infrastructure including buildings and bridges that may need repairing for the cracks and delamination of concrete.

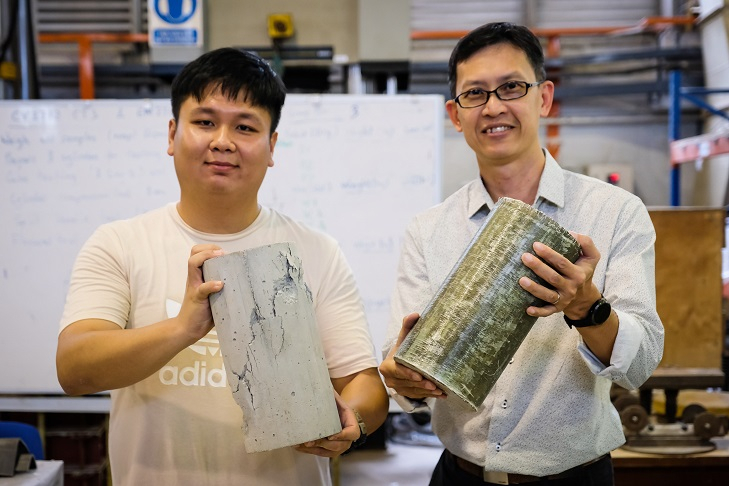

NTU, JTC and Prostruct Consulting Pte Ltd scientists and engineers, who created this new technology, named it Fast Wrapping Fibre Reinforced Polymer or FasRaP.

In a news release, NTU stated that the genius minds behind this technology had used commercially available glass fibres, including a proprietary glue-like resin developed by NTU materials scientists that allows the wrap to stick on.

It should be noted that the glue-like resin only becomes harder when it comes under the light. Such uniqueness helps it to be "pre-applied in the factory and packaged into a ready roll of sticky wrap, similar to double-sided tape."

The news release added that "When brought to the work site, FasRaP is ready to be applied directly on the wall or pillar," and to complete the job only three workers are needed. On the other hand, currently available FRPs in the market needs a team of six people to install because of the conventional resin, which requires to be applied manually on the work site.

NTU posted a video on their social media platform that showed how FasRaP works and claimed that the innovation is capable of strengthening a structure by 80 percent. The video also filmed a 'load test' comparing a bare concrete pillar without reinforcement and a pillar wrapped with FasRaP. It even showed how much effective this technology is to resist a bomb blast.

Assoc Prof Ng Kee Woei, lead project investigator from NTU's School of Materials Science and Engineering said that because of this innovation, many companies now can save manpower costs, increase efficiency and make structural reinforcement much easier to execute.

Prof Woei, who is also the Principal Investigator at the NTU-JTC Industrial Infrastructure Innovation Centre (I3 Centre) also believes that FasRaP will help those companies to "meet future building standards and prolong the life of older buildings and structures as Singapore and other urban cities age."

Calvin Chung, Group Director of Engineering at JTC said that "By combining our engineering knowledge, NTU's research expertise and Prostruct's industry know-how, we can address real challenges faced by the construction industry such as manpower constraints and quality control."

"The development of new advanced materials such as FasRaP will help us meet the growing demand for the repair and rehabilitation of ageing infrastructure in Singapore by significantly reducing the time and improving the quality of installation, thereby increasing productivity and cost efficiency," Chung added.

The co-investor of this project, Dr Ang Choon Keat, founder of Prostruct Consulting Pte Ltd, a specialist professional engineer and certified blast consultant mentioned that FasRaP is suitable for strengthening any structure against blasts.

The research team, which includes scientists and engineers, is currently working to commercialise this technology and to materialize the plan, the co-inventors JTC will identify suitable infrastructure projects to deploy FasRaP.